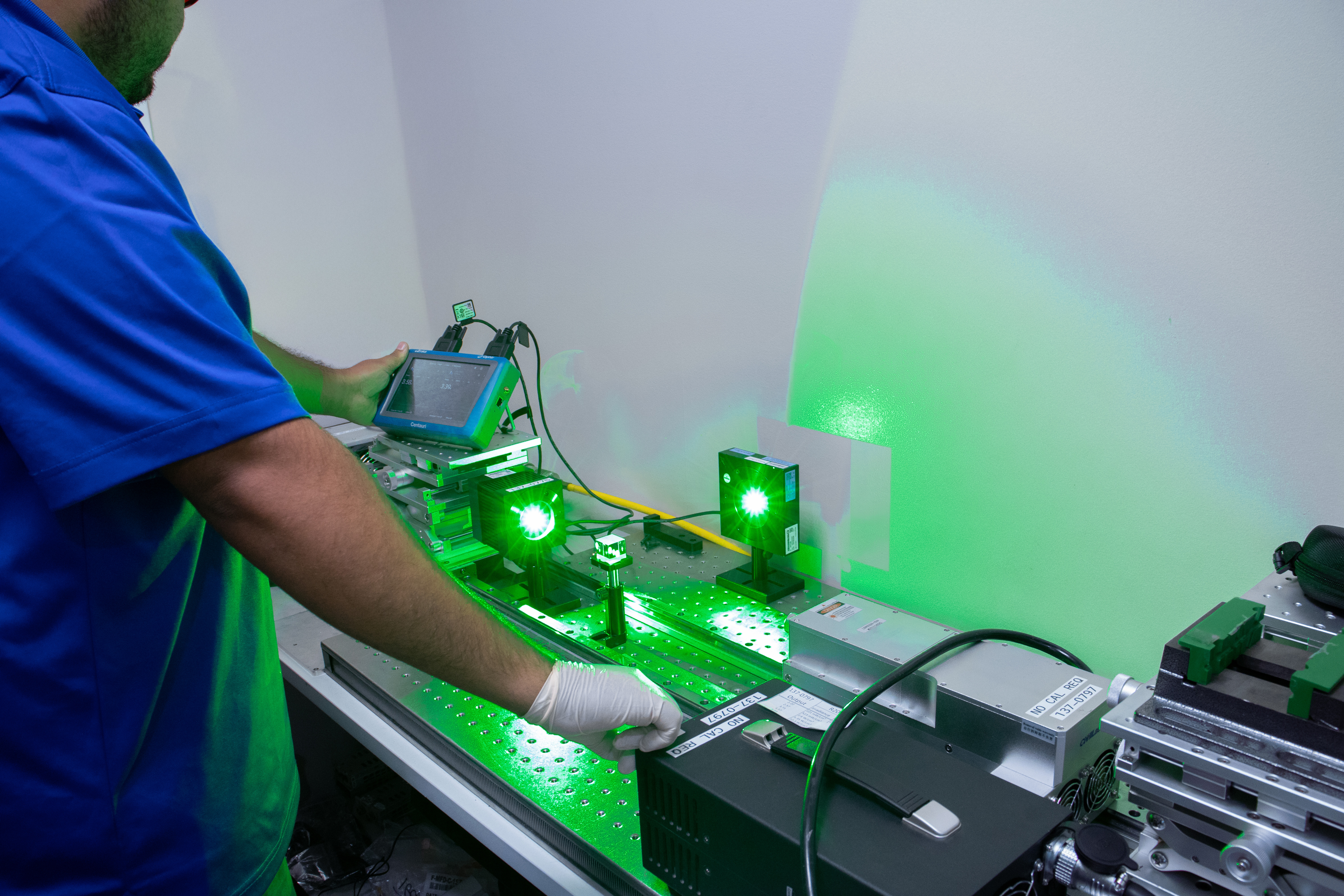

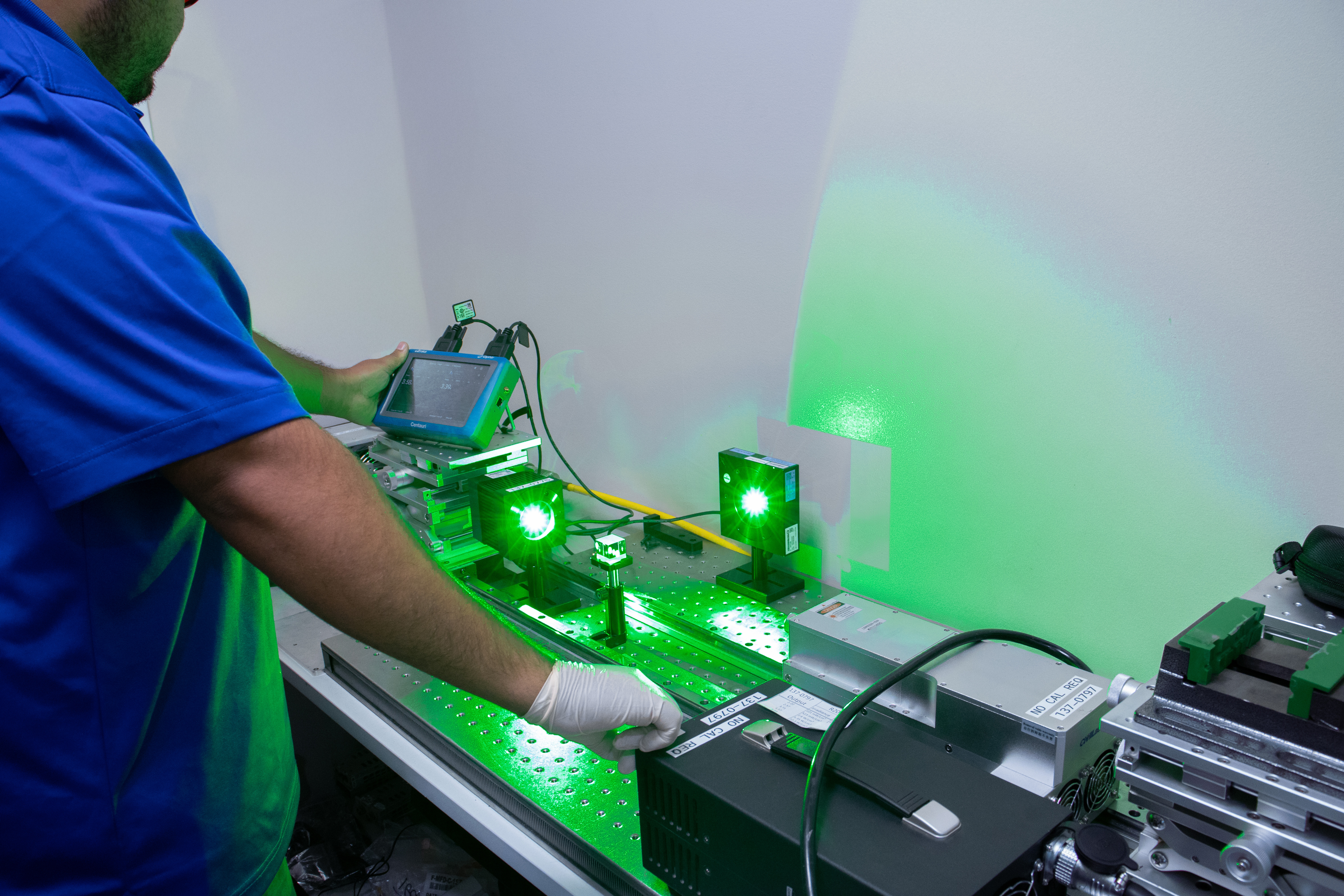

Laser energy and power measurement

Laser sensor calibration is essential to verify that instruments measuring laser power or energy are functioning correctly. We calibrate the devices that monitor lasers, just as a thermometer measures temperature. This ensures that every measurement accurately reflects reality, preventing risks, waste, and failures in critical processes.

Our service ensures that your measuring equipment delivers reliable results, supporting the quality of your operations in sectors where precision is non-negotiable, such as the medical, automotive, high-tech electronics, manufacturing, and aerospace industries.

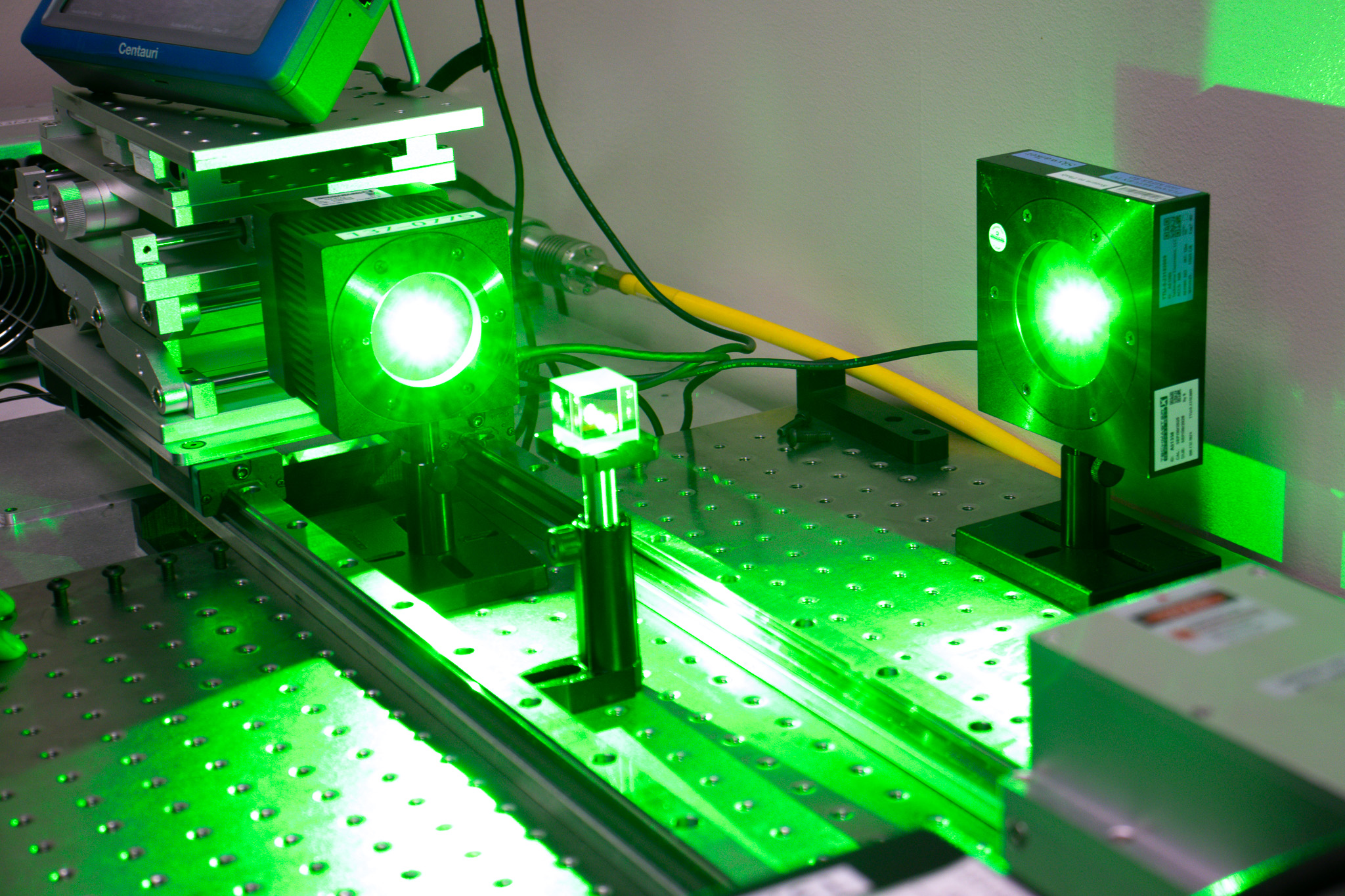

Types of instruments we calibrate

Laser power sensors

Laser energy meters.

Cutting and welding heads with integrated detector

Laser sources (output characterization)

Get a quote or schedule your calibration service

Click hereScope

ViewWavelengths –

532, 1064 and 10600 nm

Measured power –

up to 5000 W

Power generated –

1 mW to 300 W

Energy –

up to 20 μJ

Industries we serve

![]() Medical – Surgical, ophthalmic, and dental lasers.

Medical – Surgical, ophthalmic, and dental lasers.

![]() Automotive – Laser cutting, engraving, and welding.

Automotive – Laser cutting, engraving, and welding.

![]() Manufacturing – Laser cutting, engraving, and welding.

Manufacturing – Laser cutting, engraving, and welding.

![]() Electronics – Micromachining processes and semiconductor testing.

Electronics – Micromachining processes and semiconductor testing.

![]() Military – Targeting systems and precision optical applications.

Military – Targeting systems and precision optical applications.

![]() Aerospace – Targeting systems and precision optical applications.

Aerospace – Targeting systems and precision optical applications.

Our competitive advantages

It is essential to mention that we are pioneers in Mexico in the accredited calibration of laser power and energy sensors and meters. With 30 years of experience supporting the industry, we offer a reliable, timely service of the highest quality, ensuring accuracy in every process and providing peace of mind for our clients.

Using our service is equivalent to

Having accurate measurements that guarantee the quality of your critical processes

Comply with international quality standards and audits without complications

Preventing risks and failures in medical, industrial, or high-power applications

Optimize resources by reducing errors, waste, and rework