Tests for compressed air systems

At Techmaster de México we are governed by a constant search for innovation, we listen to our clients and their needs. We are happy to contribute to the development of each one of them.

We are pleased to announce that we have added new tests for compressed air systems. We recognize that there are thousands of companies with specific needs in this area. All our tests act under the ISO-8573 standard.

We invite you to consult our Scope and learn about the scope of our quality system with the incorporation of these important tests .

Our tests for compressed air are based on the ISO 8573 Standard, we list our tests:

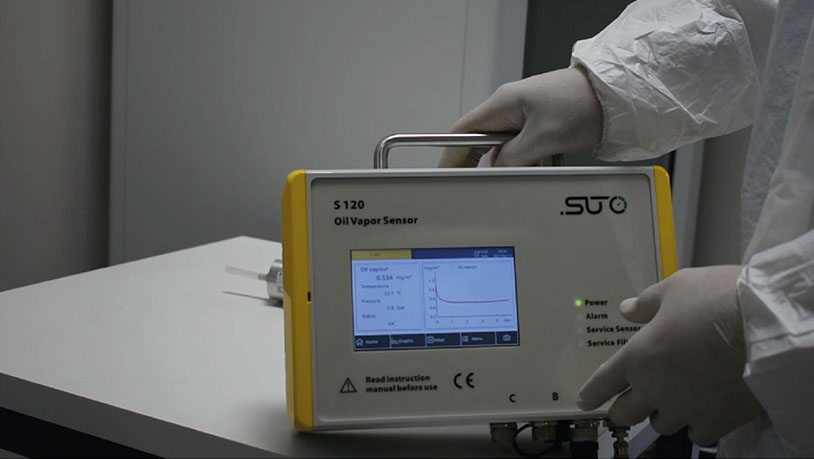

Oil Aerosol & Vapor Content, Compressed Air Purity Test

Humidity / Dew Point Measurement, Compressed Air Purity Test

Pressurized Air Particle Content, Compressed Air Purity Test

Viable Microbiological Contaminant, Compressed Air Purity Test

Ensures the purity of compressed air; removes or reduces the range of contaminants in it. It will be a pleasure to contribute to the quality of your compressed air systems.

What pollutes compressed air?

The Compressed Air and Gas Institute (CAGI) cites 10 contaminants that typically must be removed or reduced from the low-pressure compressed air used for manufacturing (not breathing air). These contaminants are classified into four general categories:

- Particles (from scale in pipes, wear particles and atmospheric dirt)

- Water (liquid, vapor and aerosol)

- Oil (liquid, vapor and aerosol)

- Microorganisms

How often should tests be done?

The tests are recommended to be carried out every year, but this depends on the customer's verification parameters.

When is compressed air polluted?

Contamination depends on several factors, on the quality of the filters, on the temperature, on the pressure. This is precisely what the tests are for, to detect whether the compressed air is contaminated. Pollution can be caused by the compressor taking in air from outside to supply the compressed air system, from there it goes to a storage tank. Poor quality filters or already deteriorated filters can cause the ingestion of microorganisms or particles, in addition to the fact that the air contains other pollutants such as hydrocarbons, oils, water, etc. Water and steam can deteriorate the system by oxidizing the walls of the the tubes and generating particles.

There are other systems where Nitrogen or CO2 gas is used as the air supply, these being stored in an airtight tank, reduce the possibility of being contaminated by particles or microorganisms, but by Being a gas, they are exposed to pressures and temperatures that can change their state of matter and thus generate steam, oil and liquids.